Predictive Maintenance Machine Learning

How Machine Learning is Revolutionizing Predictive Maintenance (And Saving Industries Millions)

Predictive Maintenance Machine Learning

Beyond the Breakdown : How Machine Learning is Revolutionizing Predictive Maintenance (And Saving Industries Millions)

Let’s face it, unexpected equipment failure is a nightmare. It grinds production lines to a halt, sends maintenance crews scrambling, costs a fortune in lost revenue and emergency repairs, and can even compromise safety. For decades, industries have relied on reactive maintenance (fix it when it breaks) or preventive maintenance (fix it on a set schedule, whether it needs it or not). But what if you could know when a machine was really heading towards failure, with enough time to plan the perfect repair? Enter the game-changer: predictive maintenance machine learning.

This isn’t science fiction; it’s the powerful fusion of sensor technology, vast data streams, and sophisticated algorithms that’s transforming how we care for critical assets. Think of it as giving your machines a voice – a voice that whispers warnings long before the catastrophic scream of failure.

Why the Old Ways Just Don’t Cut It Anymore

-

Reactive Maintenance (Run-to-Failure): This is pure firefighting. It’s incredibly expensive due to unplanned downtime, potential collateral damage, expedited shipping for parts, and overtime labor. Imagine a critical conveyor belt snapping during peak production – chaos!

-

Preventive Maintenance (Time-Based): Changing oil every 3 months or replacing bearings annually, regardless of actual condition. This reduces unexpected failures but introduces its own waste: perfectly good parts get replaced early, and unnecessary downtime is scheduled. It’s like changing your car’s tires every 10,000 miles even if you only drive on smooth highways.

-

The Gap: Neither approach truly understands the actual health of the asset in real-time. They operate in the dark, leading to either costly breakdowns or unnecessary maintenance spend.

Predictive Maintenance Machine Learning: Shining a Light on Machine Health

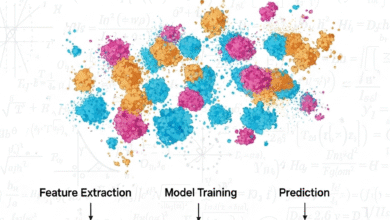

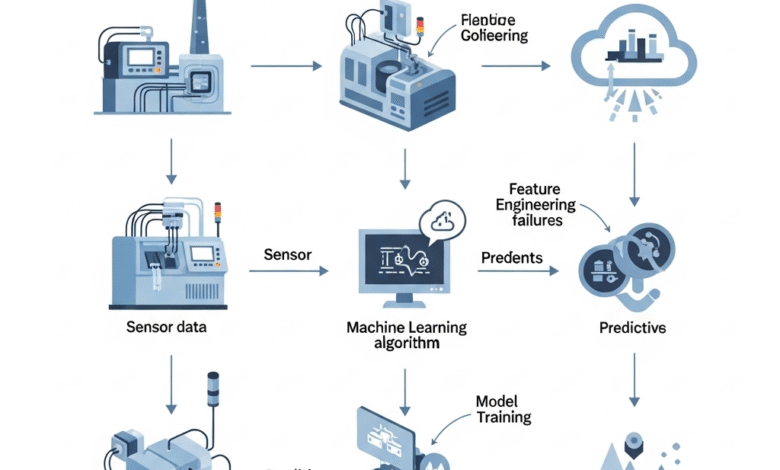

Predictive Maintenance (PdM) aims to predict failures before they happen by monitoring the actual condition of equipment. Machine Learning (ML) is the rocket fuel that makes modern PdM not just possible, but incredibly powerful and scalable. Here’s the magic formula:

-

Sensor Up: Machines are instrumented with sensors (vibration, temperature, pressure, acoustics, current, voltage, etc.) that continuously collect data.

-

Data Deluge: This creates massive streams of time-series data – the digital heartbeat of your equipment.

-

ML Alchemy: This is where predictive maintenance machine learning works its wonders:

-

Learning Normal: ML algorithms (like Autoencoders or clustering – K-Means, DBSCAN) learn the complex patterns of what “healthy” operation looks like for each specific machine under various loads and conditions.

-

Spotting the Anomalies: By comparing real-time sensor data to the learned “healthy” baseline, ML can instantly flag subtle deviations – the earliest whispers of trouble. This is anomaly detection.

-

Diagnosing the Problem: More advanced ML techniques (like classification algorithms – Random Forests, Support Vector Machines, Gradient Boosting, or even deep learning – CNNs for vibration images, RNNs/LSTMs for sequences) can analyze the nature of the anomaly. Is it bearing wear? Imbalance? Lubrication issues? Electrical faults? ML helps pinpoint the probable root cause.

-

Predicting the Future: The crown jewel: prognostics. Algorithms (often regression models or specialized survival analysis models) analyze the trend of the degradation signals. They don’t just say “something’s wrong,” they estimate Remaining Useful Life (RUL) – predicting when the component is likely to fail with a certain confidence level. This is the crystal ball for maintenance planning.

-

Prescribing the Cure: Emerging ML applications are starting to suggest optimal maintenance actions based on the diagnosed fault, predicted RUL, available resources, and production schedules – moving towards true prescriptive maintenance.

-

The Tangible Benefits: Why Industries Are Racing to Adopt Predictive Maintenance Machine Learning

The ROI isn’t theoretical; it’s concrete and compelling:

-

Massive Downtime Reduction: Unplanned outages are slashed. By fixing issues during planned windows, production continuity soars. Studies show reductions of 30-50% in downtime are achievable. That translates directly to revenue saved and customer orders met.

-

Dramatic Cost Savings: Reduce emergency repairs, minimize unnecessary preventive part replacements, optimize spare parts inventory, and extend the overall lifespan of assets. Maintenance costs can drop by 20-40%.

-

Enhanced Safety: Predicting catastrophic failures (like a turbine blade disintegrating or a press brake malfunctioning) is paramount for protecting personnel. PdM creates safer work environments.

-

Optimized Resource Allocation: Maintenance teams shift from firefighting to strategic planning. Resources (people, parts, tools) are deployed precisely where and when they are needed most.

-

Improved Product Quality: Equipment operating outside optimal parameters (even if not failing immediately) can produce defects. PdM helps maintain consistent quality by keeping machines in their ideal operating window.

-

Extended Asset Lifespan: By addressing issues early and preventing catastrophic failures, the overall operational life of expensive machinery is significantly prolonged.

-

Data-Driven Decision Making: Move from gut feeling or rigid schedules to decisions grounded in real-time machine health intelligence.

Where Predictive Maintenance Machine Learning is Making Waves Today

This isn’t niche tech; it’s transforming core industries:

-

Manufacturing: Monitoring CNC machines, robots, conveyors, presses, pumps, motors. Preventing line stoppages is critical for JIT production. (Imagine an automotive assembly line avoiding a $1M/minute stoppage!).

-

Energy (Wind, Oil & Gas): Predicting failures in wind turbine gearboxes, generators, and bearings (often in hard-to-reach locations) is vital for maximizing uptime and reducing costly crane operations. Monitoring pipelines, compressors, and drilling equipment offshore.

-

Transportation & Logistics: Predicting failures in aircraft engines (a pioneer in PdM), train locomotives and components, truck fleets, and even warehouse automation systems.

-

Utilities: Monitoring transformers, turbines, and switchgear in power plants and across the grid to prevent blackouts.

-

Healthcare: Predictive maintenance on critical medical imaging equipment (MRI, CT scanners) and hospital facility systems (HVAC, generators).

Implementing Predictive Maintenance Machine Learning: Your Roadmap

Ready to move beyond breakdowns? Here’s how to get started thoughtfully:

-

Identify Critical Assets: Not every machine needs ML-powered PdM. Focus on assets where failure has severe consequences (safety, high downtime cost, expensive repairs).

-

Sensor Up (If Needed): Ensure you have the necessary sensors collecting relevant data. Modern IIoT (Industrial Internet of Things) platforms make this easier than ever.

-

Data Foundation is Key: Garbage In = Garbage Out. Ensure data quality, consistency, and accessibility. You need historical data (including failure logs if possible) to train models. This is often the biggest hurdle.

-

Define the Problem & KPIs: What exactly do you want to predict? Failure of a specific component? General anomaly? Define clear success metrics (e.g., % reduction in unplanned downtime, increase in Mean Time Between Failures – MTBF).

-

Build or Buy?: Develop in-house ML expertise (data scientists, ML engineers, domain experts) or partner with specialized vendors offering predictive maintenance machine learning platforms. The vendor route often accelerates time-to-value.

-

Start Small, Scale Smart: Pilot on one or two critical assets. Prove the value, learn the process, and then expand systematically. Don’t try to boil the ocean.

-

Integrate with Maintenance Systems: The predictions need to flow seamlessly into your CMMS (Computerized Maintenance Management System) or EAM (Enterprise Asset Management) system to trigger work orders efficiently.

-

Build a Data Culture: Success requires collaboration between maintenance teams, operations, IT, and data scientists. Foster a culture that trusts and acts on data-driven insights.

The Future is Predictive (and Prescriptive!)

Predictive maintenance machine learning is rapidly evolving. What’s next?

-

Deeper Integration with AI: Combining ML with other AI techniques like computer vision (inspecting parts via cameras) and natural language processing (analyzing maintenance logs).

-

Edge Computing: Running ML models directly on sensors or gateways near the machine for ultra-fast, real-time anomaly detection, even without constant cloud connectivity.

-

Enhanced Prescriptive Capabilities: ML won’t just predict failure; it will increasingly recommend the optimal repair strategy, timing, and resource allocation, considering complex constraints.

-

Digital Twins: Creating highly detailed virtual replicas of physical assets fed by real-time sensor data. ML models running on the digital twin enable incredibly accurate simulation, prediction, and optimization of maintenance strategies.

-

Democratization: Tools are becoming more user-friendly, allowing maintenance professionals with less deep ML expertise to leverage powerful insights.

Embrace the Predictive Mindset

The era of waiting for things to break or blindly following maintenance calendars is ending. Predictive maintenance machine learning offers a smarter, more efficient, and ultimately more profitable way to manage critical assets. It’s about moving from uncertainty and reaction to foresight and proactive control.

For businesses in the US and globally, the question isn’t if to adopt this technology, but how soon. The benefits – reduced costs, increased uptime, improved safety, and longer asset life – are simply too significant to ignore. Start exploring how predictive maintenance machine learning can transform your operations, one prediction at a time. Your machines (and your bottom line) will thank you.